Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

fiber packing belt production line

fiber packing belt production line

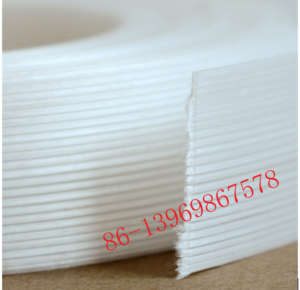

I the strap introduction

It is a new environmental protection packaging material used to replace steel strip in the world. It is more and more widely used in chemical industry, machinery, wood, medical treatment, glass, aluminum ingot, steel, papermaking, precision instruments and other industries. The polyester fiber packing belt is connected with M-shaped steel buckle. Under the condition of reasonable design, it is not only firmly connected, but also will never fall off and slip under the fastening state, which greatly improves the work efficiency and safety in the process of binding and transportation. Its advantages are as follows:

1. Strong tensile force: it has high tensile strength and can withstand the tensile force of 0.5-8.5 tons, which can replace the traditional steel strip.

2. Seismic resistance: due to its ductility and recovery after deformation, the fiber packing belt can absorb impact energy better than the steel belt, and will not become loose after the goods shrink or expand. After packing, it can not relax for a long time and effectively absorb the vibration in transportation, so as to ensure the excellent impact resistance of goods in long-distance transportation,

3. Safety: it is light and soft, and does not need to work with gloves; When it is cut, it will not pop off and hurt transport workers and customers. Because of its soft texture, the used tape is not only very easy to handle, but also flexible texture. At the same time, it can protect the surface of the product from scratch.

4. High buckle strength: the fiber packing belt is characterized by connecting steel buckle, which is the most firm connection mode and can be tightened repeatedly; In some applications, the packing buckle can be reused.

5. No rust and deterioration: the fiber packing belt can withstand the changes of various climatic conditions, can work normally at 130 • C, has good corrosion resistance, can also work in seawater, and will never contaminate your products.

● high buckle strength: the strapping belt is characterized by connecting steel buckle, which is the most firm connection mode and can be tightened repeatedly; In some applications, the packing belt, buckle and can be reused.

● safe use: it is light and soft, and does not need to work with gloves; When it is cut off, it will not pop off and hurt transport workers and customers; Because of its soft texture, the used tape is also very easy to handle; There are no sharp edges and corners, and the forklift tire will not be damaged during storage.

● no damage to the product: the flexible texture can protect the surface of the product from scratch.

● no rust and deterioration: it can withstand the changes of various climatic conditions and will never contaminate your products.

II What are the tensile properties of the tape:

1. High strength and strong material like steel;

2. Light and soft, weighing less than 20% of the iron sheet;

3. There are no sharp edges that will damage the goods and will not scratch the workers during use;

4. It will not rust or rot or deform;

5. It is applicable to a wide range of temperature and climate, and can work normally at – 40 ℃ – 130 ℃;

6. Strong linearity and system tension;

7. It can cushion huge impact during transportation;

8. Good flexibility, no deformation, high crossing and folding;

9. High efficiency, convenient and fast use, less waste, safe use and removal (recyclable).

| Width of strap 带子宽度 | Tensile strength 强度 | Weight of each meter strap

一米带子重量 |

|

| 32mm | 2600kg | 36g | |

| 32mm | 2000kg | 30g | |

| 25mm | 1440kg | 22g | |

| 25mm | 1250kg | 22g | |

| 19mm | 920kg | 16g | |

| 16mm | 690kg | 11g | |

| 13mm | 488kg | 9.3g |

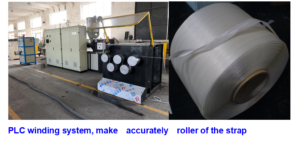

III machinery introduction

Our company combines the advantages of American and Italian equipment and our long-term experience to design and manufacture equipment with high efficiency, low energy consumption and high quality packing belt。 we exported many sets of machine to Turkey. followings are our machine parts introduction.

1. fiber release system

Perfect designing according to the yarn and straps need. consist of frame, fiber clips.

Adopt woven industrial special fiber treatment parts.

The fiber can release freely without twisting and damage.

Easy to install yarn , protection yarn without broken.

2. heating oven for the yarn

use to remover water from the yarn. ensure produce high quality straps.

consist of heating bars , fiber circle rollers , bearing, tension wheels.

all the oven body made by double layer , inner layer has insulation material to keep the thermal .

bears adopt NSK brand

3. extruder

special design screw and barrel for yarn straps.

4. mould and die head

this parts is very important in the line. Our this die head and mould design same as Italy machine design. This ensure the machine can produce high quality straps in a high speed.

this die head designed for extruder the PP straps with fiber together .

Mould Processing procedure :

material select —milling the surface of material –forging and surface harden treatment—polish—hole making—CNC precision process—surface final treat—-chromium treatment.

- Italy style design , can produce high quality straps in a high speed.

- Widely mould cave, ensure stable pressure, keep stable producing. Keep high quality of straps

- Raw material : copper and mould steel

- High precision CNC lathe processing

- Each size straps need each mould separately

- Change the mould very easy .

- Through the fiber passing the mould and die technology , come from italy This is the core technical of the machine. Because you need always change the fiber (each fiber bobbin 5kg) our design can save workers time every day at least 2hours in the change mould and fiber.

-

- 5. other details

our machine is used to produce straps for famous company: