Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

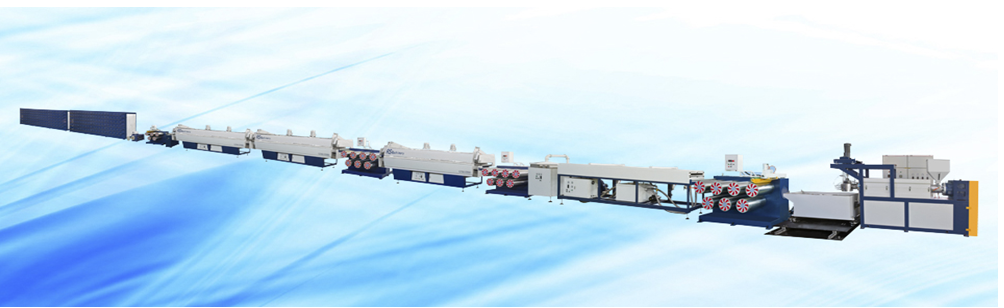

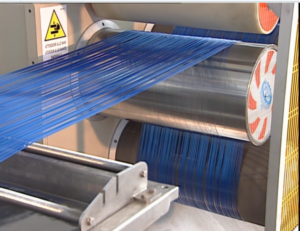

brooms, brush monofilament produce machine

brooms, brush monofilament produce machine

1. Oiled heated mixing machine

(1) Heat power: 36kw.

2. Extruder

(1) Screw diameter: 90mm; Rotation speed: 0~80rpm.

(2) L:D: 33:1; material of screw: 38CrMoALA ;

The screw structure is special designed for PET virgin or recycle material.

(3) Pressure automatic feedback system can adjust the screw speed automatically to make sure the uniform of yarn.

(4) Manual filter changer or melt filter.

(5) Screw heater: Cast aluminums heating rings with stainless steel insulation layer.

(6) Spinneret device: 1 set

(7) Heater: Electric heating ring to ensure the temperature stabilization.

(8) Two hopper dosing unit: 1 set

3. Cooling water tank: 1 set

(1) The tank is made by stainless steel 304.

(2) The height of tank is horizontal pushing structure is conveniently to disassembly the spinneret.

4. The first seven roller stretching unit

(1) Seven variable diameter rollers, material: steel pipe with hard chrome plating.

(2) Steel cabinet with accurately grind gear makes the roller run smoothly.

No rubber roller.

(3) Reducer is from Jiangsu Guomao Reducer Co., Ltd.

(4) Built-out oil lubrication system which makes the gears run steady.

5. Hot water tank for stretching.

(1) Tank length: 4000mm

(2) Heating power: 35kw, electric heating.

The temperature controlled by solid relay.

(3) The tank is made by SS 304 with the insulating layer

(4) Equip water suction unit.

6. The second seven roller stretching unit

(1) Seven variable diameter rollers, material: steel pipe with hard chrome plating.

(2) Steel cabinet with accurately grind gear makes the roller run smoothly.

No rubber roller.

(3) Reducer is from Jiangsu Guomao Reducer Co., Ltd.

7. Single layers hot blast oven: 1 set

(1) Fan power: 2.2KW×2 sets.

(2) Heating power: 22.5KW

(3) Special design of hot air channel which make the temperature evenly.

8. The third seven roller stretching unit

(1) Seven variable diameter rollers, material: steel pipe with hard chrome plating.

(2) Steel cabinet with accurately grind gear makes the roller run smoothly. No rubber

——WHY CHOOSE US——-

Die head and mould professional designing , precision processing .

we have experienced engineer , and high precision CNC machine to design and process the machine.

we provide you raw material formulation, ensure you can produce out low-cost high quality yarn.