Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

PET packing straps production line

PET packing straps production line

STRAPS INTRODUCTION

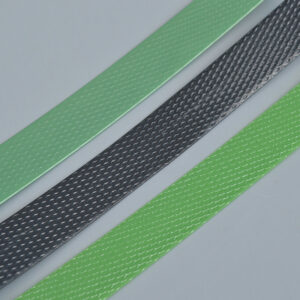

1. Pet belt, also known as plastic steel belt, is a new binding belt popular in the world to replace steel belt. It is widely used in iron and steel, aluminum, chemical fiber, cotton spinning, tobacco, paper industry, metal can and other industries.

2. Strong tensile resistance: it has not only the tensile resistance of steel belt, but also the ductility of impact resistance, which can ensure the transportation safety of your products.

3. Small elongation: the elongation is only one sixth of that of polypropylene (PP) belt, which can maintain the tension for a long time.

4. Strong temperature resistance: the melting point is 260 degrees, and it will not deform when used below 120 degrees.

5. Good flexibility: no sharp edge of steel belt, safe operation, neither hurting hands nor damaging bound objects.

6. Beautiful but not rusty: there is no problem that the steel belt rusts and pollutes the bound objects, and the color is bright.

7. Good economic benefits: the length of 1 ton plastic steel belt is equivalent to 6 tons of steel belt, and the unit price per meter is lower than that of steel belt, which can reduce the cost for you.

Machine introduction

| Material | EXTRUDER | WIDTH(MM) | STRAP QUANTITY | OUTPUT(KG/H) |

| PP | SJ65 | 5-19 | 2 | 80 |

| PP | SJ75 | 5-19 | 2 | 100 |

| PP | SJ90 | 5-19 | 4 | 180 |

| PP | SJ120 | 5-19 | 4-8 | 300 |

| PET | SJ75 | 9-19 | 2 | 150 |

| PET | SJ90 | 9-19 | 2 | 200 |

| PET | SJ100 | 9-25 | 4 | 300 |

| PET | SJ110 | 9-25 | 4 | 350 |

| PET | SJ120 | 9-25 | 4-8 | 500 |

Our company’s advangates in the PET strap machine

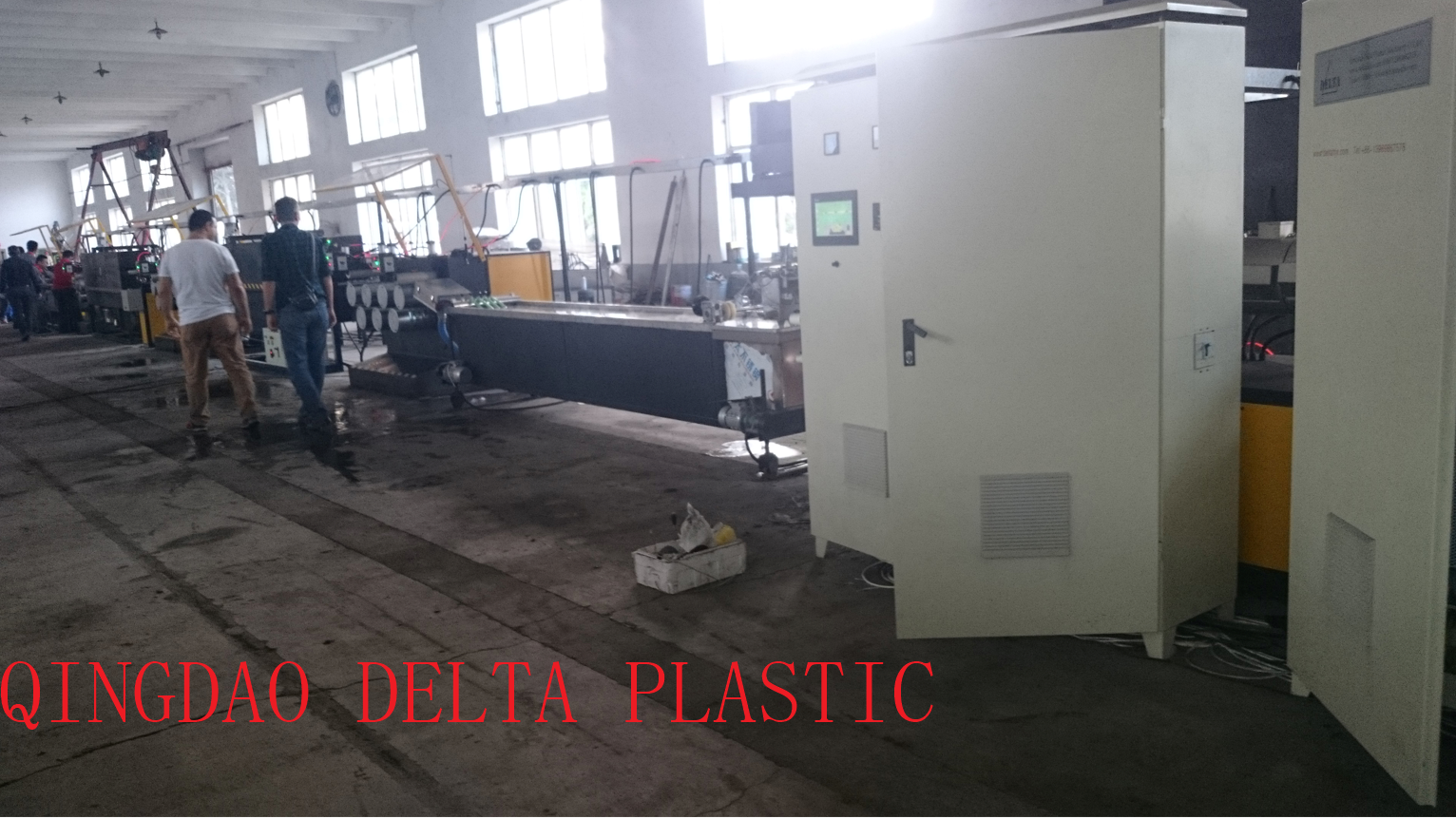

1. generally , we only make and export high quality machine. because we know after machine exporting, if machine has problems, it is very high cost to change parts and repair. so we must ensure the machine will work good in buyer’s factory

the followings are some parts of our machine

1. pre-crystallization and drying system

Molecular sieve humidity removing type. ensure the raw material water contents down to 0.3%

continously drying and crystallization system provide high quality raw material for the whole line producing.

2.high quality extruder with big capacity hopper drier .

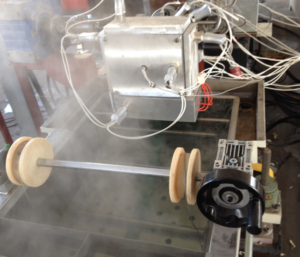

3. water tank with motor drive moving system. can adjust the height and left/right easily . installed water heating system, which can keep stable temperature to ensure strap’s accurate shape . water tank with double layer which has insulation layer, this ensure the water have a stable temperature .

4. Mould design from Italy, we have 1-6 cavities moulds. melting pump and automatic filters are all adopted high quality processed parts.

5. heating oven

Consist of air blower , heating pipe, cylinder and frequency convertor .

Our this unit a most different design is for heating energy saving. We install heaters by integrated installation. And install air blower. The air blower can blow the hot air evenly spreading in the tank. Even small capacity heaters can produce enough temperature.

- temperature controlling meter can adjust the heating temperature . air blower is adopt to make circulation air for heating. When the strap get into the box, it rise the 90℃-120℃ stretching temperature at once. This unit ensure the straps entre the first stretching roller in a stable temperature.

- has transparent view window , operator can inspect inner straps moving and heating condition .

- Cylinder open and close , convenient working.

- Heaters has thermal spreading wings. Can keep the heating in a stable and evenly spreading.

- End of the tank has sealing plate, keep the heating without any leakage.

- Length of tank: 4 meters.

- Stretch roller power:3KW

- Temperature controlling unit heating power:20KW(220V)

- Equipped with damper, control the friction force effectively.

- Air blower let the hot air flowing in the tank by circulation. The tank has insulation layer, can keep the hot air inside the tank without lost. This can save 30% electricity consumption compare with common machine.

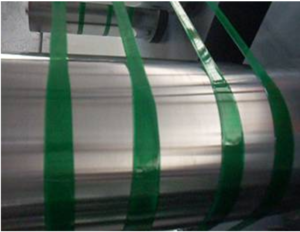

6. Stretching rollers:

Made of haul off roller, clamping unit, driving unit, bracket.

This machine’s function is ensure the straps arrive a suitable temperature before stretching . our special design can ensure the straps surface touching the heating roller’s surface in a large area , so that the double of straps surface can get evenly temperature from the rollers. Water as media and temperature controlling unit holding a stable temperature in a low consumption .

Motor power: 2.2kw

Speed: 40m /min

Media : water

Drive : gear

7. Winding system

we have common torque motor winder and also we have PLC touch screen servo motor winder.

8. PLC touch screen , close-loop full automatic system.

PLC full automatic controlling RKC /OMRON temperature controlling meter, SIEMENS low pressure electric parts.

1).10 inch siemens touch screen and control system, which is the most professional control system for plastic machinery.

2). A touched color screen for easy operation.、

3). All levels of alarm and protection function can be programmed and preset.

4). Equipped with long-distance communication interface.

5). The main and auxiliary machines can be controlled synchronously. Manual control can be used during automatic processing.

6)All the cables put in the cable channel , hang up top of the machine line.

our machine make high quality straps which can be used by auto packing tools.