Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

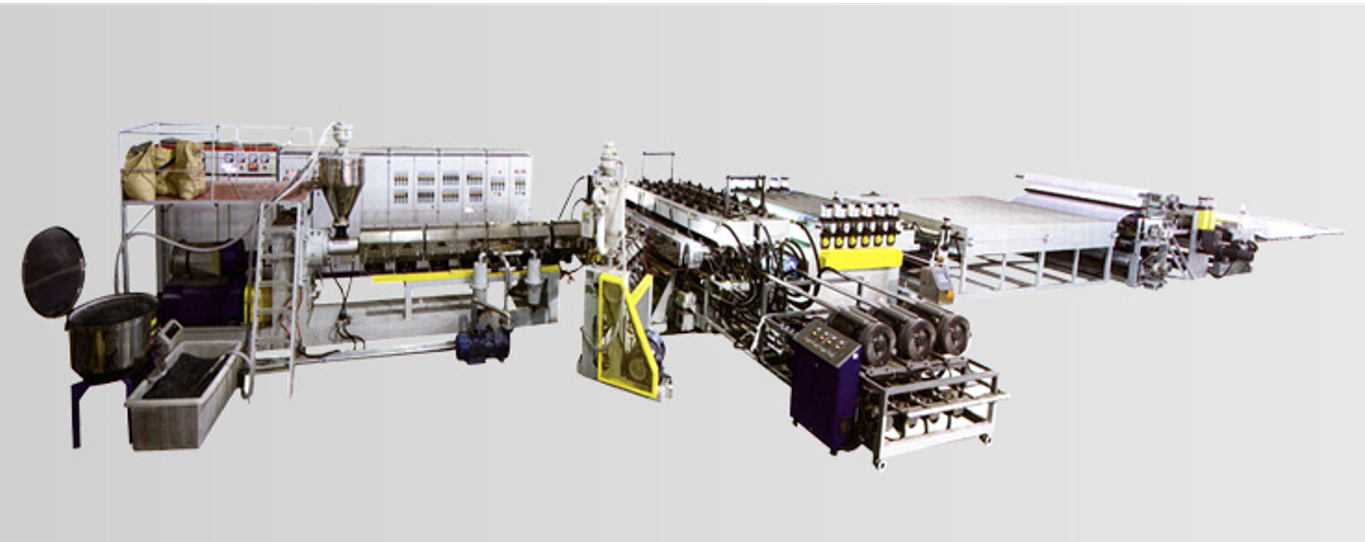

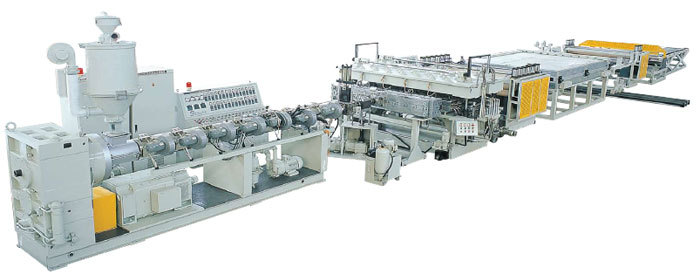

PC PP PE hollow grid board wave board machine

PC PP PE hollow grid board wave board machine

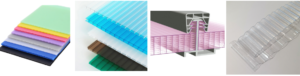

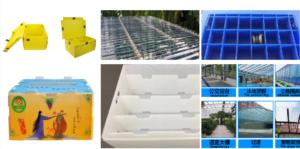

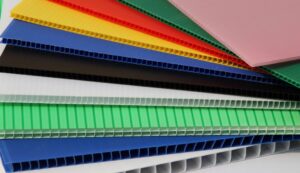

the machine can produce :

replaced paper. The trend of making corrugated board is mainly reflected in product packaging. In addition, because of the light weight, good toughness, flexible size, and relatively low cost of PP hollow board.

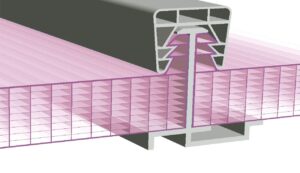

Applicable to commercial and retail buildings, sports venues, walkways with canopy, swimming pool roof etc..

Product thickness 8-30mm, Width 600-1040mm

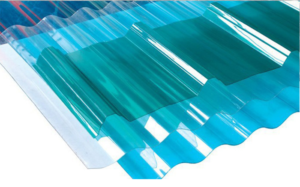

PC wave plate light weight, high strength, suitable for public, civil buildings, industrial factory lighting roof etc..

Product thickness:0.6-2mm, Waveform width 840-1050mm

canopies, office soundproofing, outdoor advertising light boxes, etc..

Product thickness:4-40mm, width 2100mm

| Model | Sheet width | Sheet thickness | Extruder Model | Motor Power |

| DELTA-1200 | 1200mm | 1.5-12mm | 100/33 | 55-75kw |

| DELTA -1800 | 1800mm | 1.5-12mm | 120/33 | 75-90kw |

| DELTA-2100 | 2100mm | 1.5-12mm | 120/33 | 90-110kw |

| DELTA-2450 | 2450mm | 1.5-12mm | 120/33 | 90-110kw |

| DELTA -2800 | 2800mm | 1.5-12mm | 150/33 | 132kw |

What’s our special :

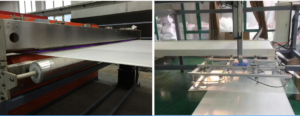

- Extruder

Specially designed extruder screw and advanced temperature control system retain the plastic properties of the polycarbonate resin while ensuring extrusion efficiency. High energy efficiency is a major benefit of this PC sheet extruder. The extruder motor consumes 20% less power than an equivalent motor made by our competitors.

Extrusion Die Multi-layer PP PE hollow grid corrugated sheet profile making machine

High quality alloy extrusion die lip and choker bar provides uniform pressure drop from die inlet to die lip. Precisely machined die assures good quality of finished extruded sheet.

3. Vacuum Calibration Table Multi-layer PP PE hollow grid corrugated sheet profile making machine

The thermal convection system of the calibration table features an intersection arrangement which ensures the hot PC resin flow is effectively cooled and the final extrudate achieves the desired shape and accurate dimensions. As far as the shape forming process is concerned, our multiwall sheet extrusion machinery allows rapid shape formation through sizing and cooling without the need of

cold water. It helps save energy and improves efficiency.

4. Dry Vacuum Calibrator Multi-layer PP PE hollow grid corrugated sheet profile making machine

The vacuum calibrator consists of 2 independent sub-systems, which are equipped with many close-loop vacuum channels.

5. Electrical Control System Multi-layer PP PE hollow grid corrugated sheet profile making machine

Programmable logic control ensures precise extrusion process parameters and optimized operation features.

- Good products come from high quality machine.