Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

HDPE PP spiral pipe, carbon black pipe , COD produce machine

COD corrugated optic duct machine

SECTION 1 BRIEF INTRODUCTION OF COD

C.O.D Corrugated Optic Duct pipes summarized formerly each kind of fiber optics, advantages in the cable guide foundation, became the new generation high performance fiber optics drive pipe by the brand-new idea development. It uses friction coefficient extremely low modified HDPE is the primary data, in the structure take the friction coefficient extremely low long wall tube as the sub-tube, bears the high pressure, the easy curving corrugated pipe is the female tube, after compound squeezes out becomes. It bears the high pressure, but is curving, has the discrimination, the easy construction is the main feature, in the physical property, the service life, aspects and so on project construction has the superiority which other many products are unable to compare

COD has very distinctive differences from the conventional telecommunication PVC ducting System.Optiroad C.O.D. opens new era of telecommunication backbone with its built-in multiple inner ducts (3 to 9) inside of the outer duct by means of assembling cable ducts in the course of production. Both inner and outer ducts are made of HDPE (High Density Polyethylene) having high flexibility enabling rolled-on spool regardless of numbers of inner ducts built-in.

Coiling Length of C.O.D. is unlimited, however depending on the numbers of inner ducts and diameters thereof; each reel may practically coiled up to 500 meters, however, coiling even 1,000 meters of small dimension model is also available.

Owing to such a flexible and lengthy product of COD, it enables quick installation reducing considerable consecutive work quantities such as trench excavation, inner duct insertion (no need as it is readily built-in), inner duct related works (such as cleaning of duct line upon completion of outer duct connection and inspection thereof) and installation time.

Owing to such benefits, great savings of project cost as well as traffic trouble are anticipated contributing to the construction of telecommunication infrastructure.

| Type | Duct in(mm) | Sub Duct in(mm) | weight | |||||

| OD | ID | thickness | OD | ID | thickness | kg/mtr | ||

| Maximum tolerance= +-2mm | ||||||||

| Corrugated duct /3duct

|

110 | 90 | 10 | 42 | 36 | 3 | 2.12 | |

| Corrugated duct /4duct

|

38 | 32 | 3 | 2.69 | ||||

| Corrugated duct /5duct

|

33 | 28 | 2.5 | 2.27 | ||||

| Corrugated duct /6duct

|

120 | 100 | 10 | 40 | 34 | 3 | 3.18 | |

| Corrugated duct /3duct | First sub duct | 110 | 90 | 10 | 40 | 34 | 3 | 2.5 |

| others | 25 | 21 | 2 | |||||

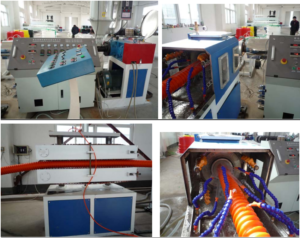

SECTION 2 The machinery to produce COD

Step 1 . sub COD production machine

We use single screw extruding machine to make HDPE sub COD. We have ability to make and amend the machine, so we can make varies of COD type very convenient by changing the mould.

Step 2. make into integrate COD by co-extrusion process.

In this step , sub COD and outer COD will make into integrate COD in one line.

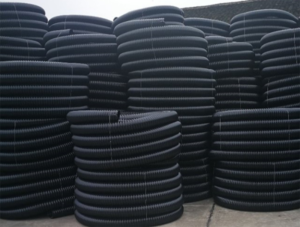

Step 3 make the COD into coil

we also provide pipe installation connections and tools

we are very professional to produce this machinery , also we produce pipe and sell.