Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

PET sheet machine

PET sheet machine

what’s the machine can produce :

1. single layer PET PETG sheet

Machine general introduction:

2. PET sheet single screw exhaust production line: this machine only needs to crystallize PET, and does not need to dry. Its advantages: low energy consumption, simple process, convenient equipment maintenance, and can ensure the blister 18CM deep cup.

3. The PET sheet twin-screw exhaust line (free from dry and crystallization) : It is launched PET sheet twin-screw exhaust line without drying and crystallization which has the advantages of low energy consumption, high efficiency.This machine is our continuous improvement upgraded products , and its central vacuum system has been upgraded. The original roots – water ring pump group upgrades to roots – rotary vane pump, which can make the vacuum degree reach 10 pa, or less. Meanwhile by using PET special alloy steel thin-wall roller unit can increase the cooling efficiency, so as to increase output, improve product toughness and transparency. we are independently programmed operating system ensures that the device is user-friendly and easy to operate.

| Model | Driving power(KW) | screw diameter(mm) | L/D ratio | Rotation speed(rpm) | Capacity(Kg/h) |

| DELT70 | 45 | 70 | 35:1 | 100 | 80-150 |

| DELT 90 | 55-90 | 90 | 35:1 | 90 | 150-280 |

| DELT 100 | 75-110 | 100 | 35/38:1 | 90 | 180-350 |

| DELT 120 | 132-185 | 120 | 35/38:1 | 90 | 250-450 |

| DELT 130 | 185-280 | 130 | 35/41:1 | 90 | 300-650 |

| DELT 150 | 220-355 | 150 | 35:1 | 80 | 400-600 |

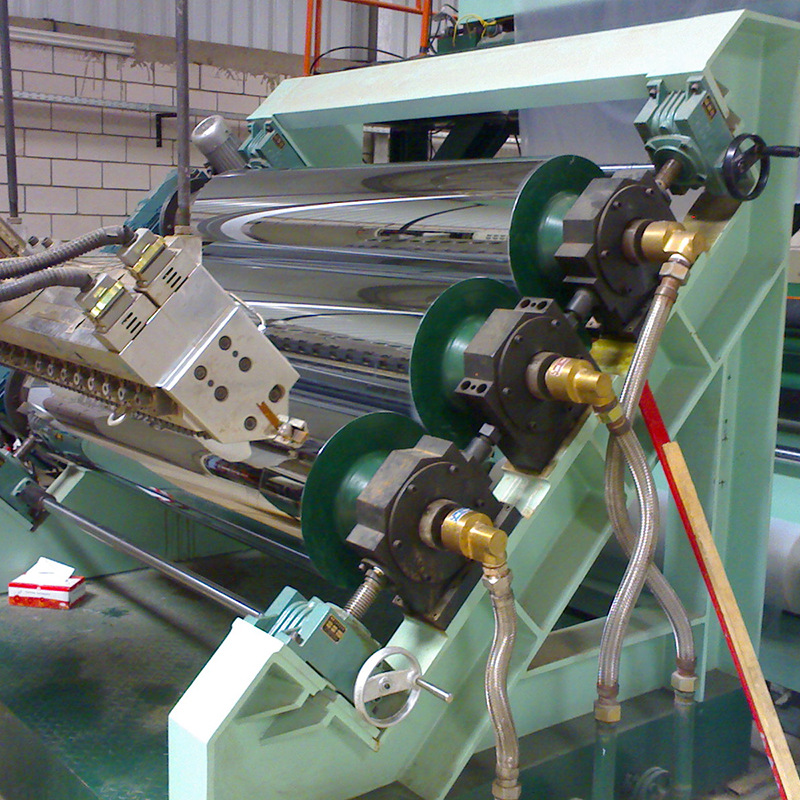

Our machine details

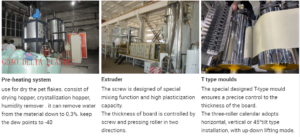

PET sheet production line is divided into two forms: pre-crystalline drying and non-drying:

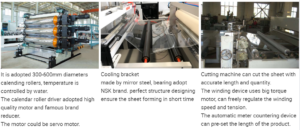

Pre-crystallization drying type extrusion line mainly consists of pre-crystallization drying system(energy saving type),extrusion system,forming system,finished product collection system;The crystal free drying type extrusion line mainly consists of extruding system(vacuum exhaust type),forming system,finished product winding system.

Products is mainly used for food packaging:fruit and vegetable packaging, toy packaging, electronic products tray etc..

Product thickness:0.1-5 mm, width 600-2000 mm