Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

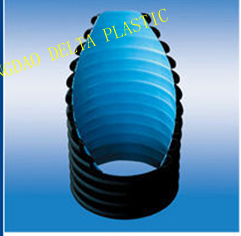

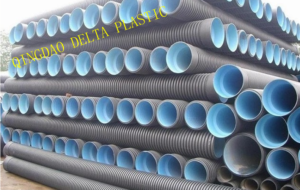

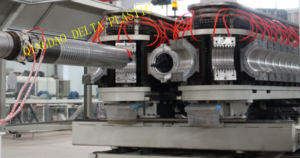

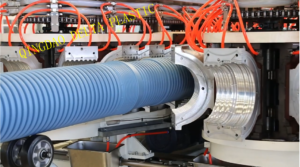

Double wall corrugated pipe production line

Double wall corrugated pipe production line

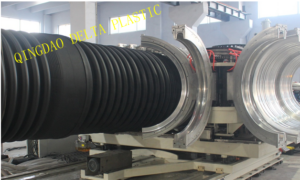

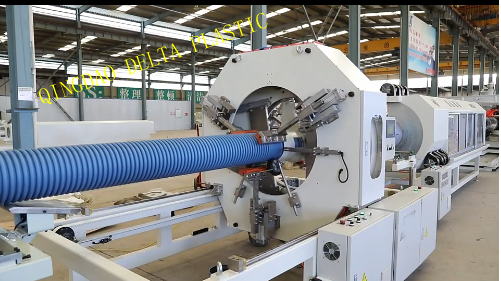

double wall corrugated pipe production line has two single-screw extruder. It has a dual-channel structure and nitriding polishing head. The forming machine adopts horizontal (or vertical) structure , advanced water cooling system, vacuum forming system, automatic lubrication system and advanced double-layer on-line expansion function. The material of the molds is aluminum alloy. The complete production line uses the German Siemens professional PLC control system. It has a high degree of automation, reliable operation, easy operation and so on.

machine and pipe general information

| Model | SGB160 | SGB250 | SGB400 | SGB600 | SGB800 |

| Structure Form | Horizontal | Horizontal | Horizontal | Vertical | Vertical |

| Pipe Diameter Range(mm) | 75-160 | 90-250 | 225-400 | 250-600 | 225-800 |

| Expansion Mode | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint |

| Forming Speed(m/min) | 0.6-5 | 0.5-5 | 0.25-4 | 0.25-4 | 0.25-3 |

| Max. Extrusion Output | 200 | 350 | 600 | 700 | 850 |

| Number of Mold Blocks(pairs) | 48 | 48 | 40 | 32 | 32 |

| Centre Height(mm) | 1000 | 1150 | 1150 | 1600 | 1600 |

Extruder

The extruders use buffer forced feeding section, the power consumption of the main drive motors is reduced by about 30%;

The flow channel section of the extruder is optimized to ensure the production of pipe at low temperature and low pressure.

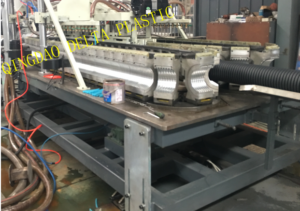

Die Head and Calibration sleeve.

Both outer layer and inner layer are extruded inside die head. Each material flow channel inside die head is placed evenly. Each channel is after heat treatment and mirrorpolishing to ensure material flow smoothly. Also die head provides compressed air between both layer.Calibration sleeve is used to cool inner layer to form smooth and flat pipe inside. Pressure water flows inside calibration sleeve to have good cooling effect. Vacuum is created on calibration sleeve surface when producing big diameter pipe, ensure inner pipe roundness.

Mould

Extrusion mold material: 40Cr. Calibration mold material: Wearable tin bronze .precision processing

Forming unit

Strong structure, practical designing . special design to reduce the friction between the moulds, enlarge mould using life. Rise pipe produce speed.

The patented closed loop direct water recycled cooling system, changing moulds no need to disassemble water tubes;

No platform design, different specifications of the moulds have same center height;

Patented drag chain design reduces equipment impact and improves service life of equipment

Cutter.

Cutter controlled by Siemens PLC, double knife cutter. Equipped with precise inspection device ensures the cutter accurately placing at the correct position of double wall corrugated pipe. Whole cutting process is accurate and fully automatic.

Double blades cutting process to remove waste pipe, ensure seamless connection of pipe;

The precise trigger device ensures continuously precision cutting;

Equipped with dual hydraulic system, symmetrical center, smooth operation

Pipe produced by our machine has the following advantages :

- Due to the structure of corrugated pipe, it has a higher ring stiffness than smooth pipes at the same weight;

- From OD40mm to ID1500mm corrugated pipe production for different application.

- Double wall corrugated pipe saves material compared to HDPE pipes at same diameter and same ring stiffness;

- Double layer corrugated pipe has a deflection of up to 30%;

- PE or PP both ok; Virgin and recycled high density polyethylene can be both used depending on different usage;