Product Category

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

- vacuum cleaner hose and pool suction hose production line

- Plastic flexible and spiral hose produce machine

- PP PET packing strap and monofilament produce machine

- PP PE PVC solid wall pipe produce machine

- Profile products produce machine

- WPC profile and board produce machine

- Irrigation hose produce machine

- Waste plastic recycle and granulator machine

- PET PP PVC EVA board and sheet produce machine

- Auxiliary machine

Contact us

Address: No. 128 B, Binzhou Road, Fu’an Industrial Park, Jiaozhou City, Qingdao City, Shandong Province

Contact: Sun Caiyun

Phone: 008613969867578

Tel:086-532-82291786

Fax:086-532-82291787

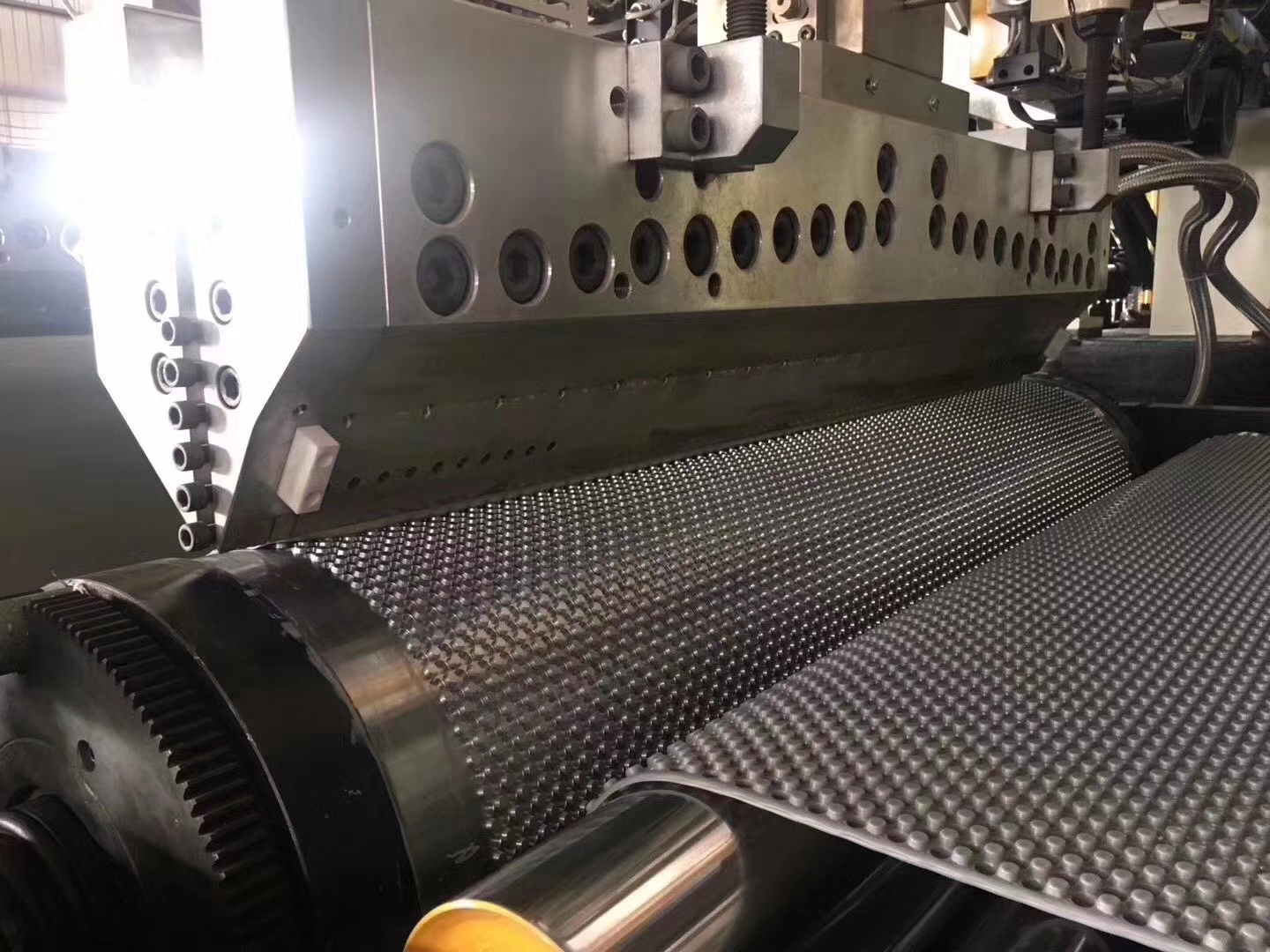

Honeycomb board produce machine

honey comb board produce machine

Application

Can be used for heavy-duty accessory backing plates, automotive interior materials, interior trim panels, tailboard backing plates, tire cover plates, high-speed rail/RV/car interiors, etc.; billboards, circulation boxes, large hoarding boxes, knife cards , Barriers, construction industry, stacking compartments, mechanical heavy parts compartments, house decoration, etc.

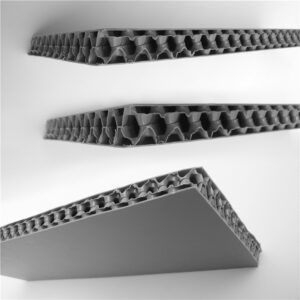

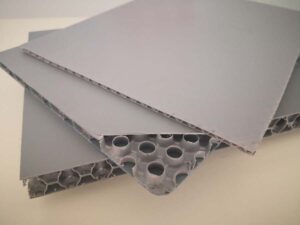

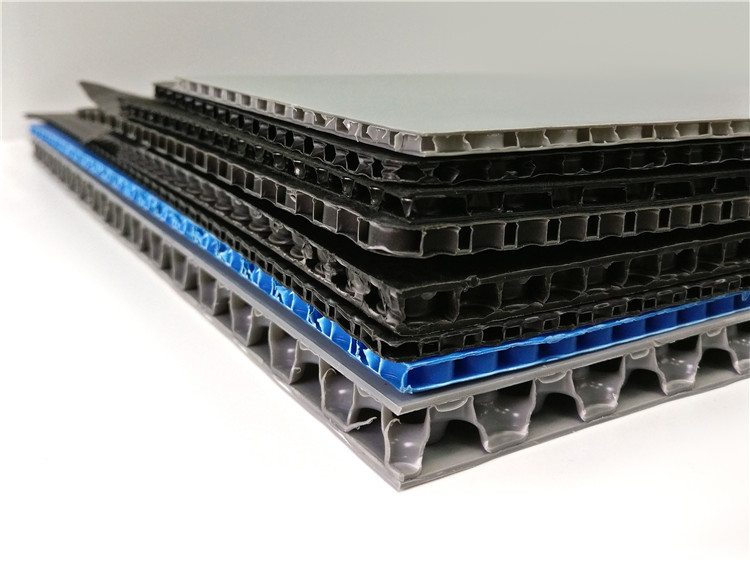

PP Honeycomb board is a three-layer sandwich board that is formed online by extrusion method. According to the structure of Honeycomb, it can be divided into single-layer board and double-layer board. Plate surface can also be based on the use of surface composite decorative film, velvet and so on. PP Honeycomb board has the advantages of light weight and high strength, non-toxic, environment, shock absorption, and cool-resistant ,sound proof and heat preservation, moisture proof and heat insulation etc..

Product specification: thickness 2-20mm, width 800-2000mm.

Main uses of the product:

- It is applied to the trunk cover, trunk partition, trunk carpet base plate, side wall trim panel, ceiling and other interior parts of passenger cars

- Used in logistics turnover boxes, various packing boxes, etc

Product Features

Non-directional, light weight, durable, high strength, wear-resistant,low thermal conductivity, good shock resistance, sound insulation, non-absorbing, easy to clean, conductive, antistatic, flame retardant function can be added and other functions.